Turbines are essential as a vessel to convert available energy at some form into useful mechanical work. In other words, they move using designed motion into energy consumption. Turbines are used in hydroelectric plants, gas and steam turbines and the like on a wide range of equipment.

The nozzle is one of the most important parts in any turbine. The nozzle essentially a small, narrow duct that serves to control the flow of fluids or gases which drive the turbine. Which means; the fluid or gas that will be moving in to turbine blade is directed and manipulated from this nozzle.

Increasing the power of electricity are made possible by improving nozzle functionality. This optimization process involves engineering the nozzle to correspond with specific application needs like gas/liquid flow rate, velocity, temperature; and pressure and composition.

In addition, the optimization of a nozzle can increase fuel efficiency which in turn lowers cost and emissions. It is especially relevant in power generation plants, which are fueled by fossil fuels such as natural gas and oil.

Nozzle design has a very important function in the performance of turbine. Nozzles especially differ regarding form and size, each impinging forces of varying nature to the fluid or gas being channeled through them. That is why turbine manufacturers invest a great deal of R&D to ensure their nozzle design delivers the best result.

For example, the nozzle shape can dictate how fast and which way resulting fluid or gas are being relocated. The nozzle is designed such that the fluid or gas flows with in a path leading to produce maximum torque and power output.

One reason for this is that nozzle geometry, i.e. the shape and size of the interior cone extending downstream from a turbonozzle's throat orifice, can have a large influence on turbine operation. Changing the geometry of nozzle internals directly impacts pressure distribution and fluid/gas flow through your turbine, which influences how thermally efficient and successful the entire unit becomes.

As an example, a nozzle geometry that increases flow turbulence during expansion in the engine can improve mixing and combustion of fuel resulting in higher power whilst decreasing emissions. On the other hand, a nozzle with less turbulent flow is better for turbulence reduction and can improve fuel economy.

Turbine systems are relying on effective nozzle technology to optimize energy conversion. The performance of the nozzle has an effect on how well a turbine can generate mechanical work from fluid/gas passing through it.

Computational fluid dynamics (CFD) simulations are great tools for the design of nozzles and many advances have been made in this field. This allows engineers to perform a CFD analysis of the fluid or gas flow through the nozzle-assessing for inefficiencies and losses, as well as refining features of their design.

Summary: Nozzle is important role in turbine efficiency and power generation, It is essential for turbine manufacturers to implement proper nozzle design, optimization and technology to maximize the performance and efficiency of their specific applications. Connecting the dots in this way brings the unable appendage to life and highlights its necessity for a well functioning turbine decent heat transfer is still vital.

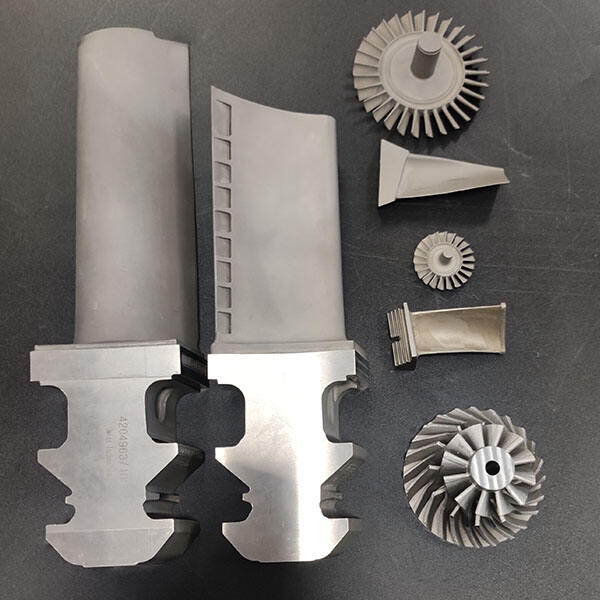

Our company offers customized services and is able to fabricate turbine components from many different high temperature alloys based on customer specifications. Our flexible production flow along with our advanced process technology and our capability to meet function of nozzle in turbine, such as size and shape, as well as performance can allow us to meet any requirement. We work closely with clients to comprehend their needs and the potential scenarios for their applications, and then give them professional guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements for applications allow us to fulfill the particular requirements of various industries and application. With our customized services, we help our customers optimize efficiency and costs of their products, and improve market competitiveness.

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to function of nozzle in turbine with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.

Our customer support is comprehensive and includes technical assistance, function of nozzle in turbine and after-sales assistance to ensure that our customers get the best possible experience. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support throughout the entire process, from choosing products, to the installation and commissioning. This guarantees that our customers can make use of our products with no issues. We have developed an after-sales service that allows us to quickly respond to customer requests and problems and provide efficient and timely solutions. Our goal is to establish lasting relationships with our customers and gain their confidence and satisfaction with quality customer service.

Our company follows strict function of nozzle in turbine standards in order to ensure excellent performance and dependability of each component. Quality control is conducted throughout the entire production process beginning with the purchase of raw materials through the test of the finished product. To ensure that the quality of our products is continuously improved, we perform regular audits and improvements. We strive to earn the trust of our clients and their long-term partnership by providing products of high-quality.